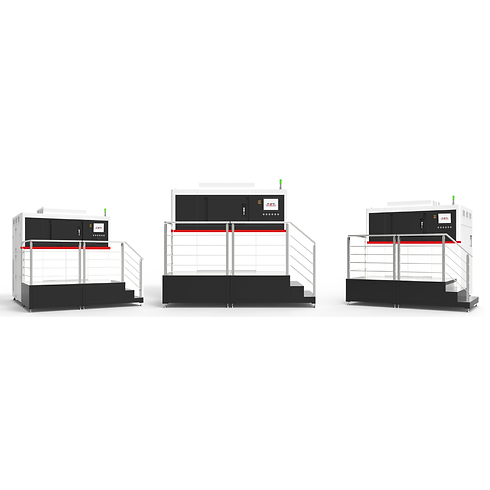

A large-scale, advanced industrial machine, supporting the growing European metal additive manufacturing ecosystem.

The machine is suitable for the custom manufacturing of single or small batch functional parts and consists of a large building plate.

A4 offers significant printing capabilities. Ideal for those who want to print extremely large, detailed objects with complex geometric shapes.

AFS SIMPLIFIES POWDER HANDLING BY AUTOMATING PROCESSES

The integration of the AFS metal powder circulation unit enhances operational efficiency by automatically sieving and reusing any unused powder.

This minimizes manual intervention and reduces material exposure, contributing to a safer and more organized working environment.

LARGE, PRECISE

PARTS

It is widely applied in industries such as aerospace and automotive manufacturing, as well as in the production of industrial tooling.

INNOVATIVE DESIGN

A streamlined, contemporary design that integrates seamlessly into industrial environments while maintaining exceptional durability and strength.

TOP-QUALITY COMPONENTS

The ANiMA A4 integrates an industrial-grade fiber laser supplied by reputable European manufacturers, purpose-built for metal powder bed fusion processes.

It delivers consistent and reliable power output and works in conjunction with a galvanometer-based scanning system, ensuring precise and repeatable laser beam placement throughout the build platform.

|  |  |  |

|---|---|---|---|

|  |

Scanning strategies and exposure settings can be tailored to suit various materials and specific component requirements. This adaptability enables both the serial manufacture of qualified parts and experimental activities, including process parameter optimization and material characterization.

MATERIALS

The ANiMA A4 is designed to work with a selection of metal powders commonly employed in industrial SLM processes, including stainless steels such as 316L, tool steels, aluminum alloys, cobalt-chromium alloys, and titanium alloys like Ti6Al4V.

These materials are widely used in industrial manufacturing due to their high strength, corrosion resistance, and favorable thermal properties.

Stainless Steels

Tool Steels

Aluminum Alloys

Cobalt Chromium Alloys

Titanium Alloys

Components manufactured on the A4 exhibit high density and strong mechanical properties, perfect for users seeking to produce exceptionally large, highly detailed components with intricate geometric structures.

Well-suited for industries such as aerospace and automotive manufacturing, as well as for the production of industrial tooling.

WHY CHOOSE ANiMA A SERIES

A New Generation of

Metal 3D Printers

The world doesn't need just additional SLM machines; it needs game-changers. A1 & A4 are the first steps in a new path, leading the way in 3D printing innovation. These aren't just machines; they are a revolution, designed to provide additional value and streamline your production process.

.png)